Indirect Fired Bent Tube Module

DRAWINGS

ADDITIONAL INFORMATION

| Indirect Fired Bent Tube Module | |

|

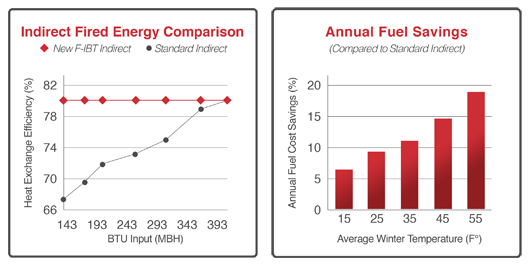

Providing clean and tempered makeup air to meet your application needs. The push-through design ensures that combustion fumes will not enter the fresh air stream. The Modular Indirect Fired Bent Module is designed to deliver clean air into an indoor environment. The IBT heater module is approved in the United States and Canada. The unit is listed to the ANSI Z83.8-2006 and CSA 2.6-2006 standards. Each furnace has a 6:1 Turndown Ratio and a maximum Turndown of 28:1 for the entire unit, depending on total required BTU Capacity and number of furnaces in the unit. Every unit is programmed to start in high fire mode to ensure consistent light-off and is equipped with an electronic, Vernier-type fully-modulating control system. The duct furnaces are all type-409 stainless steel, and certified by the American Gas Association and approved by the Canadian Gas Association. Each model utilizes a single modulating stage, and between zero and three additional ON/OFF stages depending on the required heat output. In addition, the speed of its power-vent blower on the single modulating furnace is varied as the gas flow changes, thereby maintaining a constant 80% combustion efficiency over the entire gas-firing range of the unit.

Combination packages that include both exhaust and supply fans mounted on a single roof curb are also available; please contact your sales representative for more information. |

|

FEATURES & BENEFITS

| Bent Tube In-Shot Style Furnace with Type 409 Stainless Steel Heat Exchanger | ||

| 80% Constant Efficiency over Entire Gas Firing Range | ||

| 6:1 Turndown per Furnace, 28:1 Max | ||

| Full Electronic Vernier-type Modulation | ||

| Forced High Fire Start | ||

| Variable Speed Power-vent Motor | ||

| Discharge, Space or Building Automation System (BAS) Temperature Control | ||

| Isolated and Insulated Electrical Controls Vestibule | ||

| Natural Gas or Liquid Propane Applications | ||

| Inlet and Manifold Gas Pressure Indicating Gauges | ||

| Electronic Push Button adjustment for the Modulating Gas Valve | ||

| High Temperature Limit Switch | ||

| Flame Rollout Switch with Manual Reset | ||

| LED Indicators for Troubleshooting | ||

| Economizer Inlet Air Thermostat |

OPTIONS

| 5:1 Turndown for Propane (LP) per Furnace. 23:1 Max | ||

| Up Discharge | ||

| Motorized Intake Damper | ||

| Remote Control Panel | ||

| High and Low Gas Pressure Switch | ||

| Mixing Box | ||

| Variable Air Volume (VAV) Controls | ||

| Double Wall Construction | ||

| Blower on Delay (Heat Exchanger Pre-heat) | ||

| Freeze-stat Option | ||

| Fire-stat Option | ||

| Convenience Outlet | ||

| Extended Drop | ||

| Single Point Electrical Connection | ||

| Control Cabinet Heater | ||

| Dirty Filter Airflow Switch | ||

| Auxiliary Starters | ||

| Roof Curbs | ||

| Indoor Hanging Cradle |